We are a TOTAL SOLUTION company for Pre Engineered Buildings providing designing and building services to our customers. This ensures timely completion of the project to the client’s specifications in affordable budget and desired quality.

At CRIL COATED PRODUCTS , we provide a wide range of structural steel work to suit a range of sectors and applications, including:

– Portal Frames

– Truss Frames

– Curved or Tubular Rafters

– Column/Beam Type Structures etc.

We have a professional in-house team that covers all areas of the project, including; design, manufacturing, painting and the transport of the product to ensure fluidity and prevent complications occurring within the project lifecycle.

We offer end-to-end solution for building of Pre Engineered Building Steel Structure, Industrial Shed Rafter System Building, Roof Top Structure, Multi-story or Mezzanine Floor Building, Metal Roofing & Cladding System, Prefabricated Steel Structure, Crane structure, Crane Beams, C-Purlins & Z-Purlins, Cold Storage Metal Deck Sheet, Badminton Court, Light Gauge Frame Structure (L.G.F.S.), Shopping Malls, Factories, Commercial Showroom, Office Building, Warehouse, Workshop, Poultry, Farmhouse etc.

Our team of experts and structural fabrication design team will meet with you to discuss your requirements in detail.

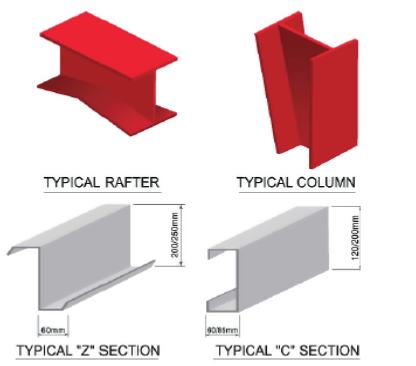

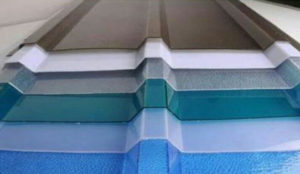

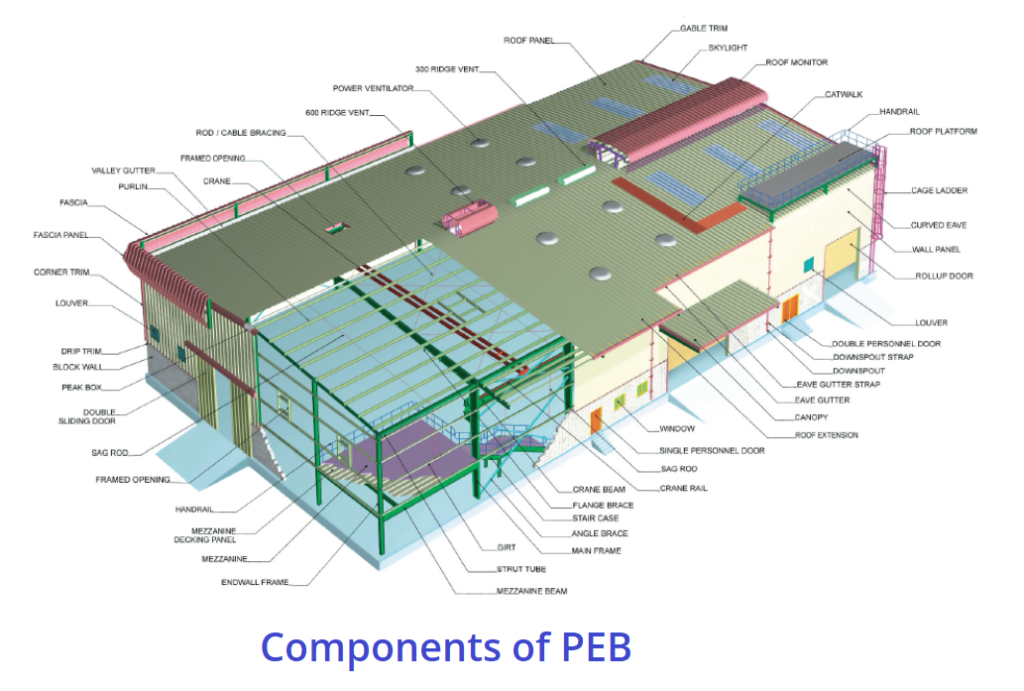

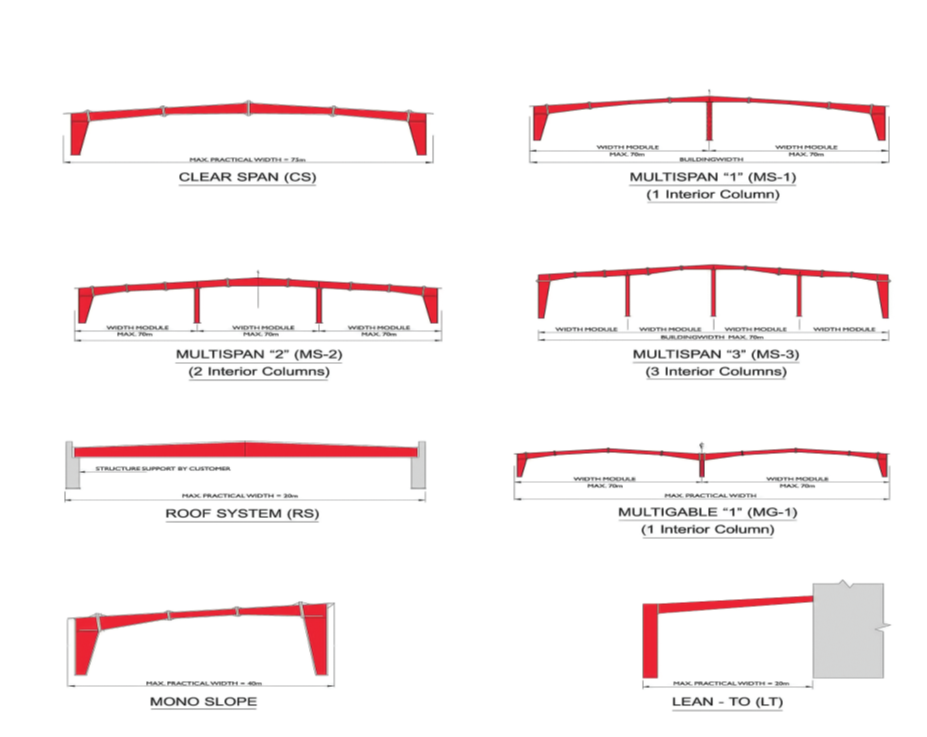

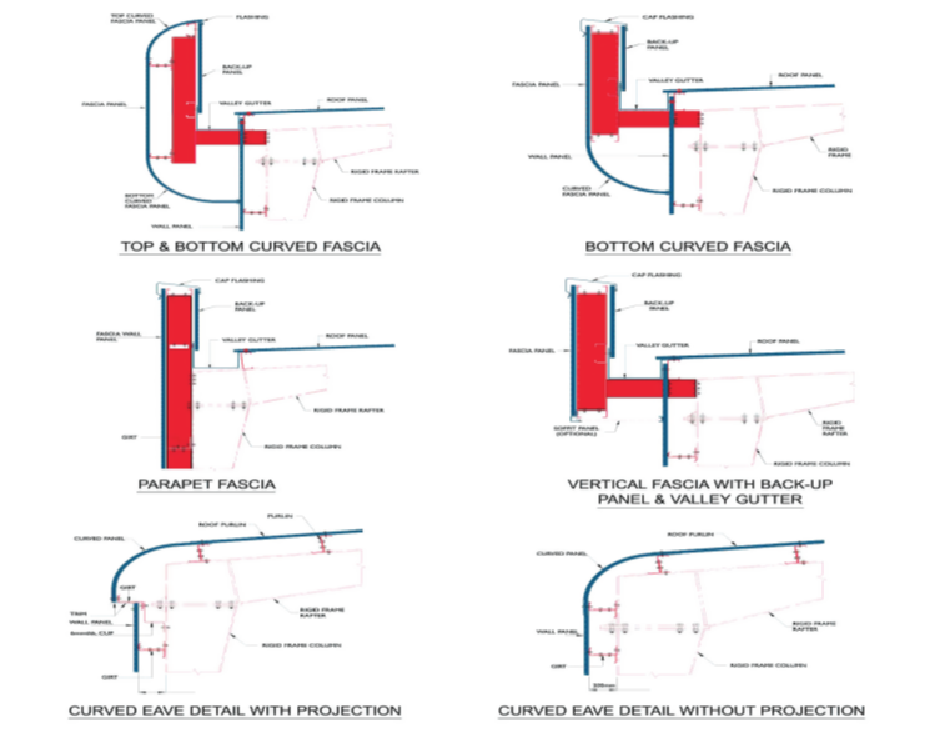

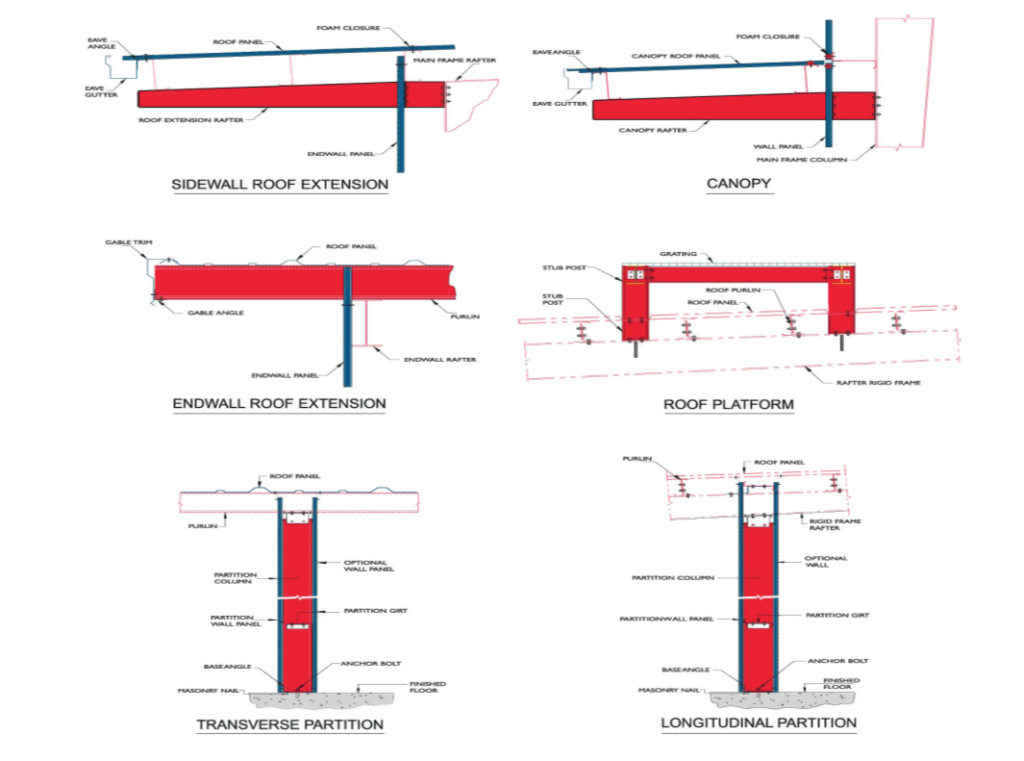

We are offering wide range of Pre-engineered Steel Buildings (PEB) that are steel structures built over a structural concept of primary members, secondary members, roof and wall sheeting connected to each other and various other building components. These buildings can be provided with different structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascias, canopies, crane systems, insulation based on the customer requirements.

These buildings and related structures are customized to suit all type of projects spanning from warehouses, heavy industrial buildings, food processing, packaging, cold storages, Hangars, thermal power plants, bridges, multi-storied buildings , Purlins for solar panels etc., with arrangement of natural ventilation using different ventilators system, natural lighting using Poly carbonate/ FRP sheets and ambient temperature control using louvers/ various insulation systems, along with various roofing solutions, based on project requirement and solutions.

Our USP

- Economical in cost

- Factory controlled quality

- Durability

- Flexibility in expansion

- Environmental Friendly

- Faster Installation

PEB Components and specifications. Please get in touch with us for any clarification and further information needed for your specific project requirements.

TIPS:

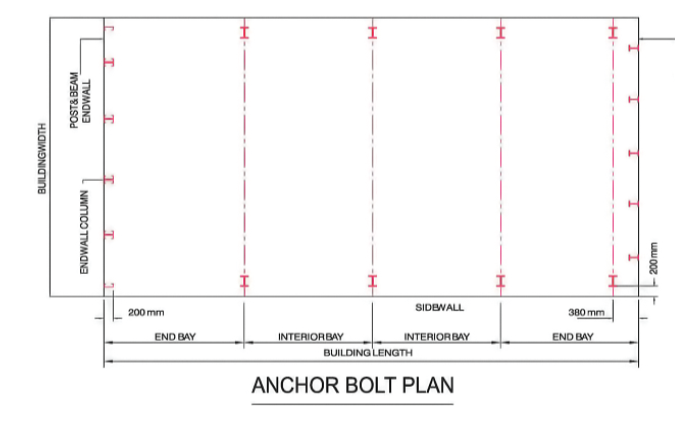

Building length

Tips: It is advisable to keep all bay lengths equal. If this is not possible, maintain all interior bays equal and the end bays equal but shorter than

the interior bays.

Buiding Width:

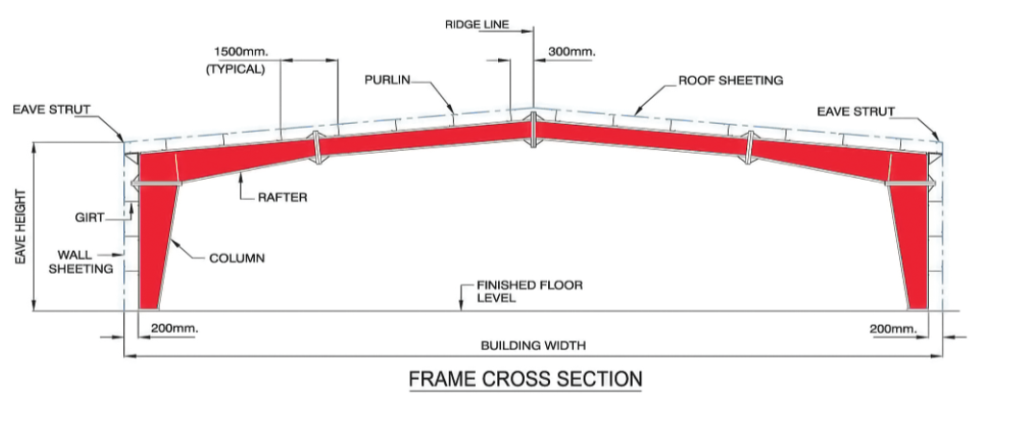

Since the roof purlins are at 1500mm c/c spacing make the building width a multiple of 3M.

UE Engineers Pre-Engineered Steel Buildings are designed by our architects solely with customer requirements in mind and within the parameters of the pre-engineered structures. Our basic architectural measures include:

Building Width is the distance from the outside of eave strut of one sidewall to the outside of eave strut of the facing sidewall.

Building Length is the distance between the outside flanges of endwall columns in facing endwall.

The end Bay Length forms the distance from the outside of the outer flange of endwall columns to the center line of the first interior frame columns.

The Interior Bay Length is measured as the distance between the center lines of two adjacent interior main frame columns which usuallyrange from 6m, 7.5m and 9m to 15m.

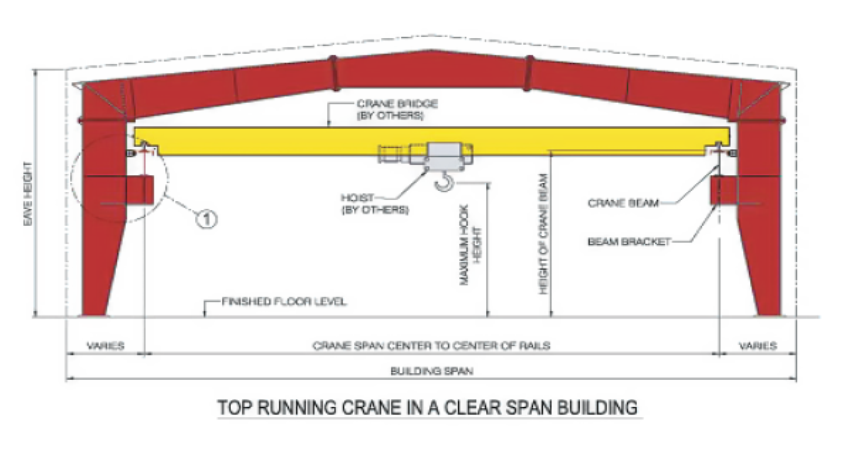

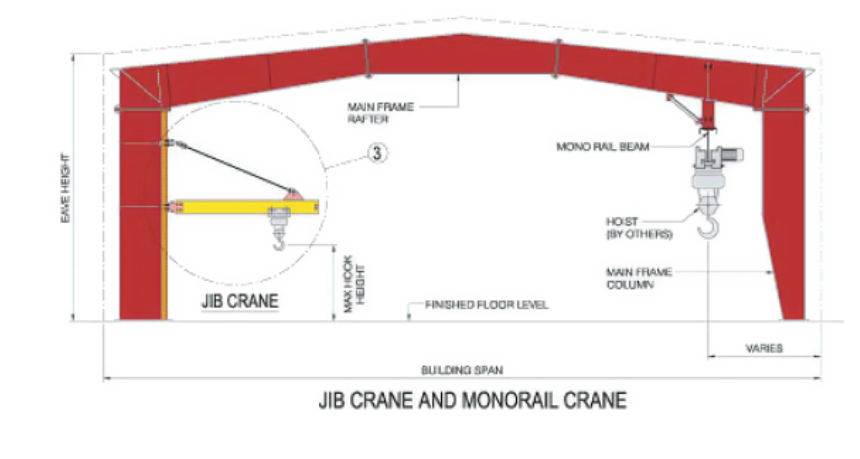

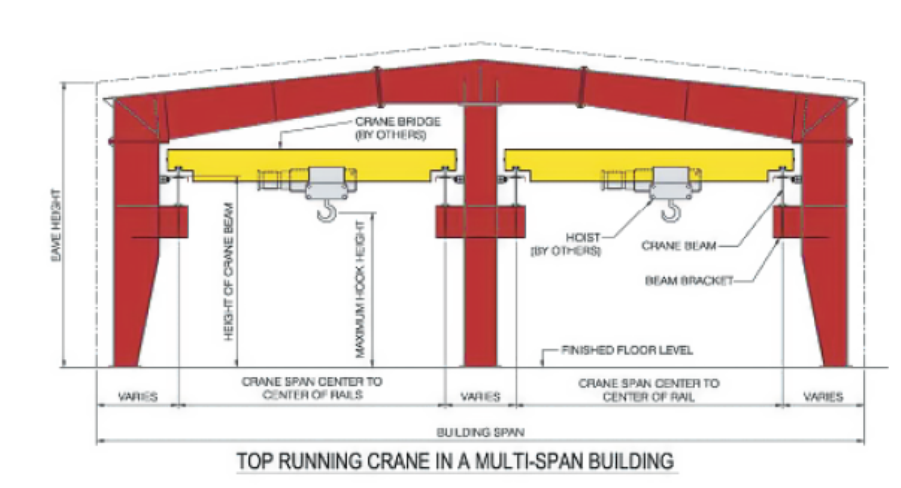

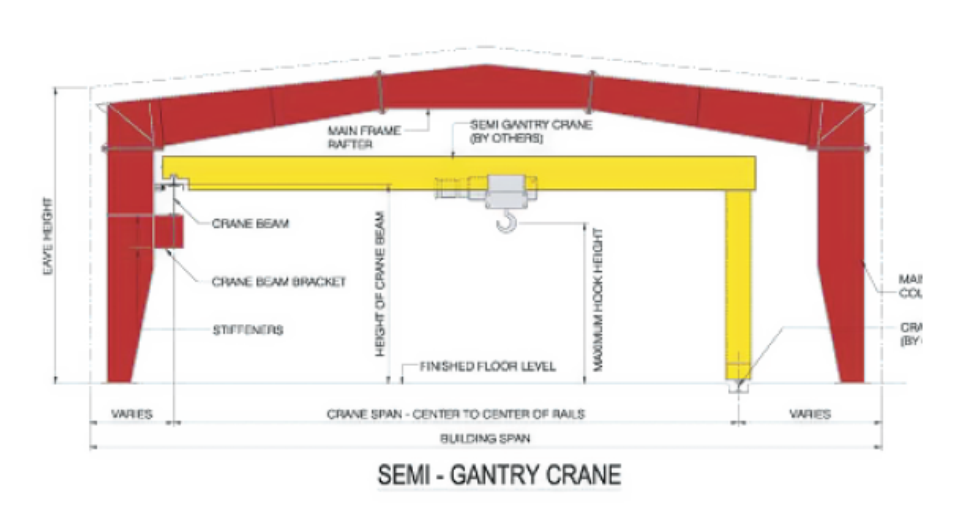

CRANE

Two out of every five metal building systems are constructed for manufacturing facilities where cranes are frequently needed for material handling.

Our building can be designed to support any required crane system. Overhead travelling cranes up to 15 metric tonnes are supported on brackets. Higher capacities are usually supported by an independent support system.

A building crane is a complex structural system which consists of the actual crane with trolley and hoist, crane rails with their fastenings, crane runway beams, structural supports, stops, and bumpers. A motorized crane would also included electrical and mechanical components. Our discussion is further limited to interior building cranes.

We do required the customer’s complete crane system information in order to design and estimate buildings with cranes.

The costs involved in adding a crane system to a metal building consist of:

1. Strengthening the building’s main frame to support the crane loads.

2. Supplying the crane brackets and crane runway beams that support the crane system.

3. Supplying and installing crane rails.

4. Supplying, installing and commissioning the Crane systems.

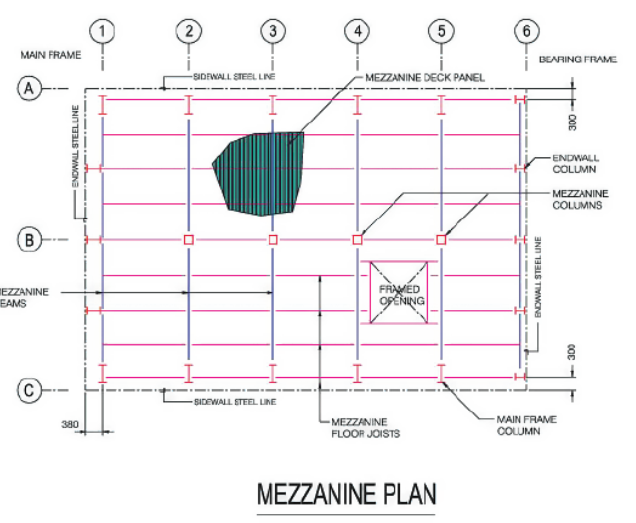

MEZZANINES

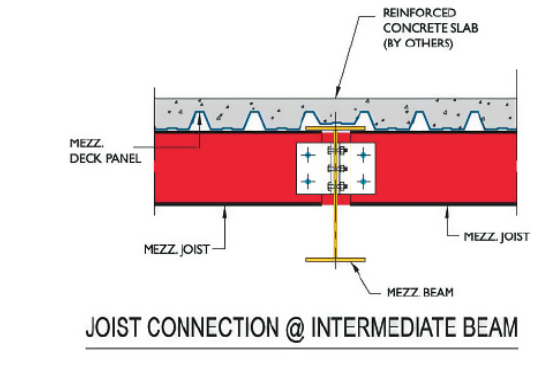

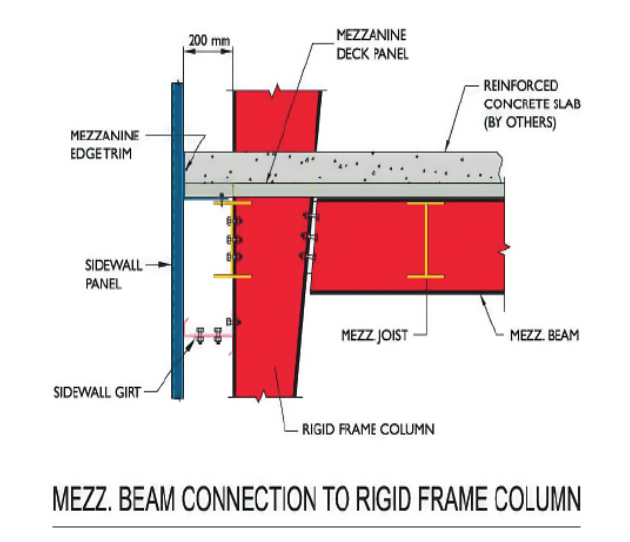

| When required by design loads, the main beams shall also be supported by intermediate columns. The primary mezzanine beams usually run across the width of the building and the joists usually run lengthwise (parallel to the roof purlins). The Economy of a mezzanine system depends on the applied loads such as dead load, live load and collateral load. | Our standard Mezzanine floor systems consist of Galvanized Steel Decking Supported by joists framed onto main mezzanine beams. A reinforced concrete slab (not Supplied by US Buildings) in cast in situ on top of the metal deck with some floor finish. |

STRUCTURAL COMPONENTS

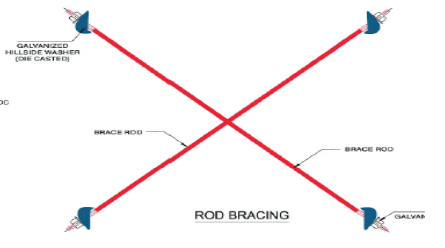

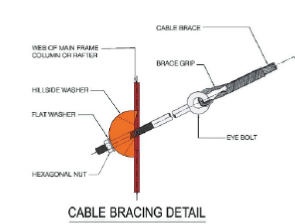

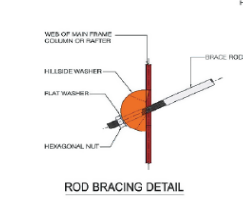

Bracing systems

Rod bracing shall conform to physical specifications of ASTM A36 Grade 36 or equivalent with minimum yield stress of 345 N/mm2