Handling and Storage

- The material should be stored under cover in dry and clean location off the ground.

- Proper care shall be exercised in the handling of all allied works at site so as not to damage the coating.

- Metal Sheets /flashings should be duly protected from damage at site, carefully stacked on firm level ground, resting on wooden blocks as supplied.

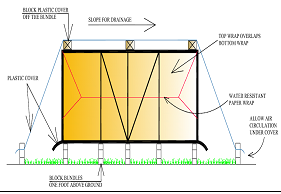

- Different sizes sheets is to be stacked separately. The sheets should be protected from waterproof covers. If stacked product becomes wet, separate it without delay, wipe it with clean cloth and stack it to dry thoroughly. (fig 1.1)

- If the bundles are stored on the ground, a plastic ground cover must be put down under the bundle to minimize condensation of water from the ground onto the sheets. Sufficient support must be provided to the raised and angled bundles to avoid excessive bowing, which may result in low spot that could hold water.

- The bundles shall be completely sheltered with a loose fitting waterproof tarp to protect the bundle during rain or snow events, but allow for air circulation and drying of condensed water. A loose tarp also shadows acthe bundle from direct sunlight and should act to moderate high temperature extremes.

- Unused portion of open bundles shall be recovered. The condition of the tarps and paper wrapping of stored bundles should be inspected daily for damage, puddles and snow accumulation. Damage to packaging or tarps shall be repaired and puddles should be removed. If water is present in the sheet bundles, the sheets shall be separated and wiped dry with a clean soft cloth and stacked with a space between each sheet, so that air circulation con complete the drying process.

- Care shall also be ensured not to keep/stack/drag any equipment/ machinery/ materials over the Metal sheets and flashings.

- The Materials to be stacked ensuring that adequate approach is there at each stage of the project layout materials in the proximity of their eventual position.

- Lifting the sheet to the desired location of roof care to be taken that rope of adequate strength and length is taken.

- Once the sheet is lifted to the desired location the sheet is to be un-hooked by the worker on roof / wall. The un-hooked sheet is to be shifted to the exact location of lying immediately.

- Materials must be stored off the ground preferably under cover and secured against the wind.

- Protect against trapped moisture and do not store near to access way.

- Do not twist flashings and avoid dragging sheets / flashings over each other.

- Ensure that the correct sheet / flashing is in the correct place and take care in handling sharp edges.

- Safety (before , During and after installation).

SAFETY : Safety is the most important part of sheet metal installation. Safety is to be followed at and every step of sheeting.

Minimum safety requirements pertaining to sheet steel installation are outlined in the following paragraphs. In the event of any conflict between these requirements and any legal regulations, the later shall apply and these requirements shall only amplify as applicable.

- The first requirement of safety is to wearing of all sorts of necessasry self protecting tools( such as safety shoes, helmet, gloves, belt etc. ).

- Then the area of working is to be barricated with safety ribbon to warn and alert workers from other trades but engaged in nearby areas.

- A close check / inspection is to be made for the hoisting equipment.

- Only healthy and medically fit workers are to be allowed to work on higher elevation.

- As getting on and off the roof is a major risk so a secure means of entry / climbing and exit / down coming is essential. A properly secured ladder is the minimum requirement at a lower level.

- While working on roof the safety belt is to be fastened with life line built on roofing system.

- During rainy day all the machines are to be checked properly to avoid any electric shock( may be fatal ). Try to avoid working on rainy day( any one carrying a roof sheet can easily be blown off the roof during stong wind

- All the openings on roof are to be very carefully covered avoid falling( human or object ).

- Always ensure that all sheeting components being hoisted to the working level shall be adequately banded and carefully slung employing steel wire rope.

- All bundles shall be tag lined during the ascent of the hoisting operation. Precaution shall be taken to avoid damage to cladding components and to prevent marring of exposed surfaces.